Produkt beskrivelse

very low maintenance costs Fully Enclosed Switched Fiber Laser Cutting Machine

Produkt beskrivelse

ACCURL-Q8800 series of fiber laser skæremaskine selection of today's most cutting-edge German IPG laser, combined with the company's own design gantry CNC machine tool system, the use of high-strength overall welding body, after high temperature annealing, large CNC milling machine precision machining; Rigidity, stability, with precision ball screw, linear guide drive operation. High precision, fast speed Mainly for the 4MM following metal sheet fast precision cutting, fiber laser with high beam quality, high brightness, high conversion rate, maintenance-free, stable and reliable operation costs such as low cost and small series of advantages, laser production It is widely used in metal handicrafts, metal products, compact machinery, auto parts, glasses, jewelry, nameplate, electronics, toys, advertising and other industries without the need for gas, air-assisted cutting at the most advanced laser cutting level.

Performance characteristics

1- excellent beam quality: focus spot smaller, more fine cutting lines, more efficient, better processing quality.

2- very high cutting speed: the same power CO2 laser cutting machine 2 times.

3- high stability: the world's top imported fiber lasers, stable performance, the key components of the service life of up to 100,000 hours.

4- high electro-optical conversion efficiency: fiber laser cutting machine than CO2 laser cutting machine electro-optical conversion efficiency of 3 times, energy saving.

5- very low cost of use: machine power consumption is only the same type of CO2 cutting machine 20-30%

6- very low maintenance costs: no laser working gas; fiber transmission, no reflection lens; can save a lot of maintenance costs.

7- product operation and maintenance convenience: fiber transmission, no need to adjust the optical path.

8- super flexible light guide effect: small size, compact structure, easy to flexible processing needs.

9- machine tool gantry dual drive structure, high damping bed, good rigidity, can withstand high speed and acceleration.

10- the model uses imported AC servo system drive and import drive system, machine tool movement using imported gear train, linear guide guide to ensure that the equipment of high speed, high precision, high reliability.

11- rack and guide with a fully sealed protective device to prevent oil-free friction movement and dust pollution, improve the life of the transmission parts to ensure the accuracy of machine movement.

12- automatic exchange table set, shorten the standby time, effectively improve the efficiency of more than 30%.

13- fully enclosed protective cover, the use of safe and secure.

14- professional laser cutting machine CNC control system, computer operation, to ensure the quality of cutting, so that cutting work more convenient, more simple and reliable operation, beautiful appearance of high-grade.

Application scope

It is suitable for all kinds of metal sheet material, pipe cutting, especially for stainless steel, carbon steel, alloy steel, diamond and other materials, all kinds of high hard brittle alloy (aluminum and alloy, copper and alloy, titanium and alloy, Excellent processing effect. Laser cutting technology in the hardware and sheet metal industry, can be part of the punch and wire cutting.

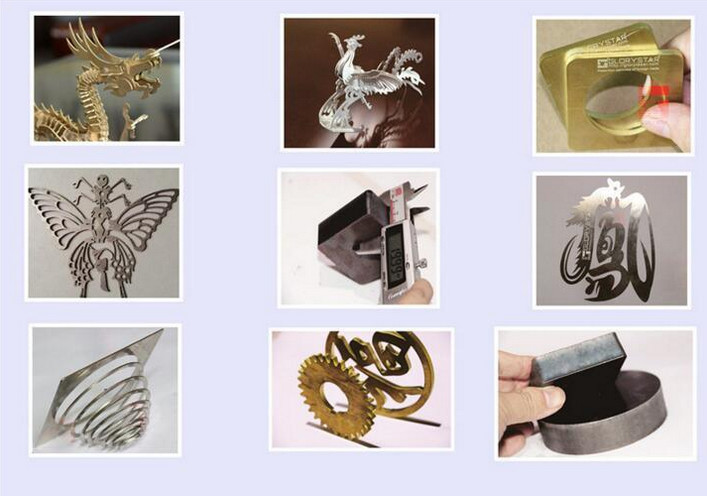

Prøver viser