Egenskaber ved vores 1000 watt laser maskine

1.Stabilitet og pålidelighed af lyssti og kontrolsystem

2. Importerede originale fiberlasere, høj og stabil funktion, levetiden er over 100.000 timer

3.Højere skærekvalitet og effektivitet, skærehastigheden er op til 80 m / min med udseende og smuk skærkant

4. Tysk højtydende reduktionsgear, gear og stativ; japansk guide og kugleskrue.

Gældende industri og materialer af fiber laser skæremaskine

fiber laser skæremaskine Ansøgning:

metalskæring, fremstilling af elektriske afbrydere, rumfart, fødevaremaskiner, tekstilmaskiner, ingeniørmaskiner, lokomotivfremstilling, landbrugs- og skovbrugsmaskiner, elevatorfremstilling, specialkøretøjer, husholdningsapparater, værktøj, forarbejdning, IT-fremstilling, oliemaskineri, fødevaremaskiner, diamantværktøj , svejsning, svejsning gear, metal materialer, dekoration reklame, laser overfladebehandling af udenlandske forarbejdning tjenester, såsom alle former for maskiner forarbejdningsindustrien.

Vores fiber laser skæremaskineApplikationsmaterialer:

Professionel, der bruges til at skære tynde metalplader, i en række højkvalitets 0,5 -3 mm kulstofstålpladeskæring, kan også skære rustfri stålplade, aluminiumslegeringsplade, galvaniseret plade, elektrolytisk plade, siliciumstål, titanlegering, aluminiumszinkplade og andet metal.

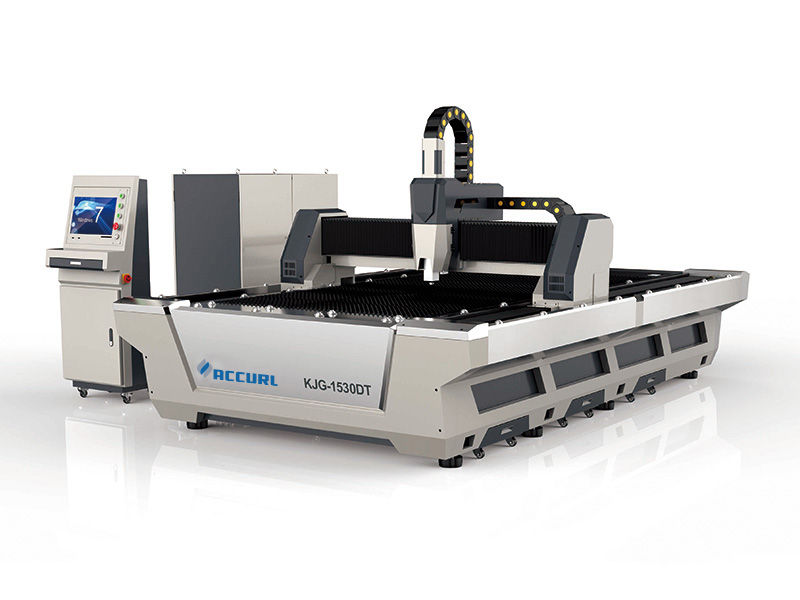

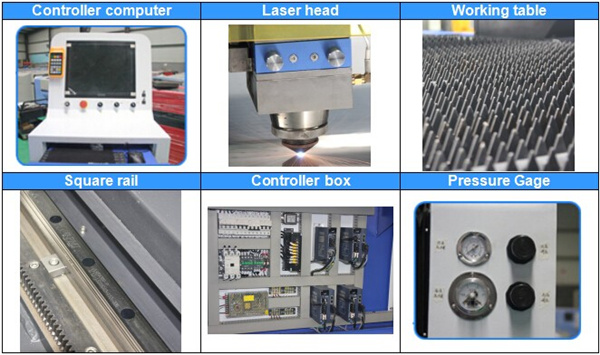

Vigtigste maskine billeder af 1kw laserskæremaskine

Hurtige detaljer

Anvendelse: Laserskæring

Tilstand: Ny

Lasertype: Fiberlaser

Anvendeligt materiale: Metal

Skæringstykkelse: 0-20mm

Skæreområde: 1300 * 2500mm

Skærehastighed: 25m / min

CNC eller ikke: Ja

Køletilstand: Vandkøling

Kontrolsoftware: bechoff ( Cypcut )

Understøttet grafisk format: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Certificering: CE, ISO, SGS

Service leveret efter salg: Ingeniører til rådighed for serviceudstyr i udlandet

Model: 1000 watt laser

Skærematerialer: Rustfrit stål kulstål Etc (Metal Laser Cutting Machine)

Fiberlasergeneratortype: Berømt mærke Raycus (fremstillet i Kina)

Fiber Laser skærehoved: Lasermech (fra USA)

Motorer og drivere: 1500W Fuji servomotor lavet i Japan

Min. Linjebredde: ±0,02 mm

Fibermodulets levetid: Mere end 100000 timer

Garantitid: Hele maskinen i 3 år (fib

Parameter af vores Fiberlaser skæremaskine

| Maskinmodel | 2500 * 1300mm |

| Laserkraft | 300W/500W/1000W/3000W |

| Fiberlaser Generator type | Berømt mærke Raycus (fremstillet i Kina) |

| Laserbølgelængde | 1064 nm |

Laser Beam kvalitet | <0.373mrad |

| Arbejdsbord | Sawtooth |

| Fiber Laser skærehoved | Lasermech (fra USA) |

| Fokuslinse | Lasermech fremstillet i USA |

| Levetid for fibermodul | Mere end 100.000 timer |

| Motorer og drivere | 1500W Fuji servomotor lavet i Japan |

| Reducer | 3 sæt fra Tyskland |

| Guide skinner | PMI-mærke med høj nøjagtighed fra Taiwan |

| Send systemet | Dual Rack & Pinion type |

| Rack system | Tyskland stativ |

| Kædesystem | Igus lavet i Tyskland |

| Vandkøler | TEYU(S&A) mærke, CW6000 |

| Kontrolsystem | Professionelt laserstyresystem - Cypcut

|

| Positionstype | Rød prik |

| Skæringstykkelse | ≤3 mm (rustfrit stål) ≤6mm (kulstofstål) |

| Maks. Tomgangshastighed | 1400mm / s |

| Skærehastighed | 300mm / s |

| Position nøjagtighed | ± 0,05 mm / m |

| Position hastighed | 20m / min |

| Min. Linjebredde | ± 0.02mm |

| Strømforbrug | ≤12KW |

| Bære vægt | 700 kg |

| Spænding | 380V/50HZ,3PH |

| Hjælpegas til skæring | Oxygen, nitrogen, luft |

| Kompatibel software | Autocad, Coreldraw osv |

| Grafisk format | Nc |

| Arbejdsmetode | PC-kontrol |

| Samlet vurdering af strømbeskyttelse | IP54 |

| Maskinens vægt | Omkring 4000 kg |

| Maskinstørrelse | 4800*2600*1800mm |

| Garanti tid | Hel maskine i 3 år (fibermodul 2 år) |

Kvalitetskontrol af 1000watt laser

Kvalitet er vores oprigtige respekt, der tilbydes alle vores kunder, og det er den vigtigste faktor for at opretholde langsigtede forretningsforbindelser med os.

Vi er altid mere opmærksomme på kvaliteten af laserskæremaskine. Standard kvalitetskontrolsystem og team er ansvarlige for at sikre produktkvaliteten i hver proces med forskellige instrumenter som laserinterferometer og lasereffektmåler.

I den mekaniske samlingsproces bruges laserinterferometeret, laserkollimatoren, måleuret og marmorpladen; I lasersamlingsprocessen anvendes lasereffektmåleren og det optiske mikroskop.